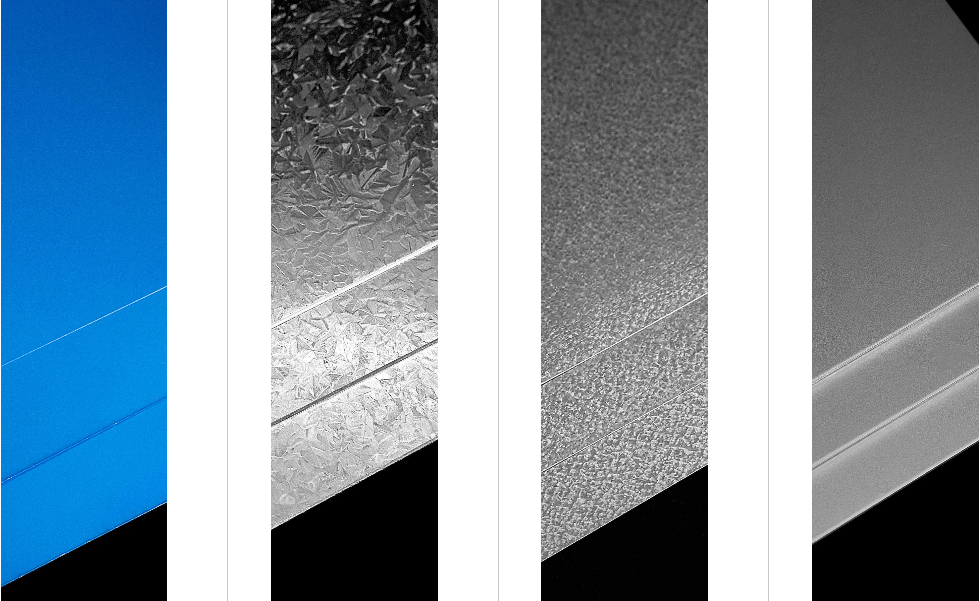

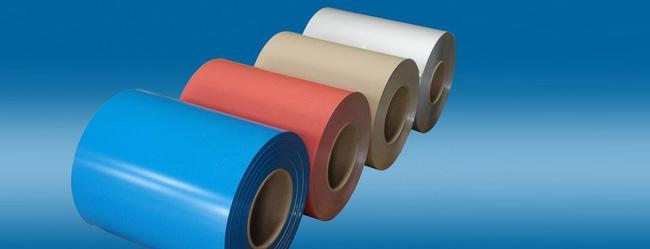

STEEL ROLLS

Viksky could supply color coated steel roll, galvanized steel roll, , Aluzinc steel roll, ZAM steel rolls etc.

Color coated steel roll, also known as PPGI (prepainted galvanized steel roll), It is a product made by using cold-rolled steel plates and galvanized steel plates as substrates, undergoing surface pre-treatment (degreasing, cleaning, chemical conversion treatment), continuously coating (roller coating method), baking and cooling. It has lightweight, beautiful and good anti-corrosion performance, and can be directly processed, achieving good effects such as replacing wood with steel, efficient construction, energy conservation, and pollution prevention.

Galvanized sheet also known as GI, refers to a steel plate coated with a layer of zinc on its surface, it has been widely used in the construction industry before being used as a color coated substrate. The surface state of its coating is in a cast state, with uniform and bright zinc spangles on the surface (in automotive and home appliance galvanizing, rough surfaces without zinc spangles are highly favored), and there are different surface states.

Aluzinc steel roll refers to the addition of aluminum (passivation protection) on the basis of zinc to the steel plate coating, with a general composition of 55% aluminum, 43.5% zinc, and 1.5% silicon. It has excellent atmospheric corrosion resistance, which is 2-5 times that of galvanized steel. It also has the high-temperature corrosion resistance of aluminum plate, with a smooth surface and good appearance, but its coating's forming and welding resistance are slightly poor.

ZAM steel rolls

ZAM steel rolls refers to the addition of a certain amount of AL to the existing hot-dip galvanized coating Coated steel plates with Mg or a certain amount of Mg element added to hot-dip aluminum zinc coatings have the characteristics of high corrosion resistance and high edge protection performance. The results of publicly available laboratory accelerated experiments and outdoor exposure experiments indicate that within a certain range, AL increase in Mg content will enhance corrosion resistance by several to ten times. Another major advantage of adding Mg to the coating is the improved corrosion resistance of the cutting edge of the steel plate. Zn based corrosion products containing Mg will cover the surface of the cut, forming protection for the cut.